Modified PTFE parts

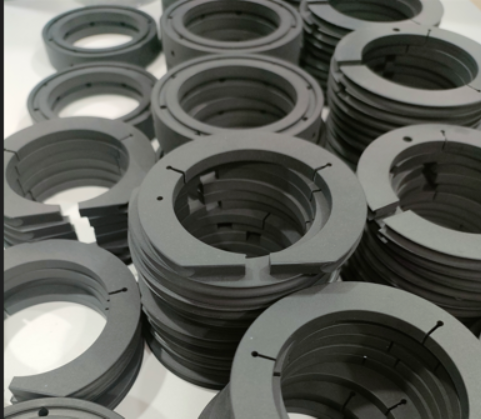

Custom Carbon fiber filled PTFE parts

Carbon filled ptfe parts

Carbon fiber filled polytetrafluoroethylene (CF/PTFE) composites have good chemical resistance, high mechanical properties, strong damage resistance, high fracture elongation and good fracture toughness. Due to its mature production technology, it can be widely used in hydraulic cylinders, cylinder sealing elements, fluid transmission machinery and other industries. The carbon fiber particles are rigid, and the high priority bearing capacity reduces the wear of the composite, so the greater the carbon fiber filling amount, the higher the hardness and compressive strength of the PTFE composite. Carbon fiber filled polytetrafluoroethylene is especially suitable for water as the medium, but it is not suitable for oxidizing medium.

Inquire Now

Descriptions

Carbon fiber filler ptfe parts

THE PROPERTY FOR CARBON FIBER FILLED PTFE

Carbon fiber filled polytetrafluoroethylene (CF/PTFE) composites have good chemical resistance, high mechanical properties, strong damage resistance, high fracture elongation and good fracture toughness. Due to its mature production technology, it can be widely used in hydraulic cylinders, cylinder sealing elements, fluid transmission machinery and other industries. The carbon fiber particles are rigid, and the high priority bearing capacity reduces the wear of the composite, so the greater the carbon fiber filling amount, the higher the hardness and compressive strength of the PTFE composite. Carbon fiber filled polytetrafluoroethylene is especially suitable for water as the medium, but it is not suitable for oxidizing medium.

THE INTRUCTION OF MODIFIED PTFE

The mechanical properties of PTFE can be greatly improved by adding any filler that can bear the sintering temperature of PTFE. At the same time, keep other excellent properties of PTFE.

Filling materials mainly include: inorganic filling materials, mainly including glass fiber, graphite, molybdenum disulfide and carbon fiber;

Metal filling materials usually use iron, copper, bronze, lead, molybdenum, tungsten, silver and other metals and their oxides to fill PTFE, especially copper and its alloys;

Organic filler materials are mainly organic fibers and polymer.

PROCESSING METHOD

Planer, Drilling, Milling and other machining methods

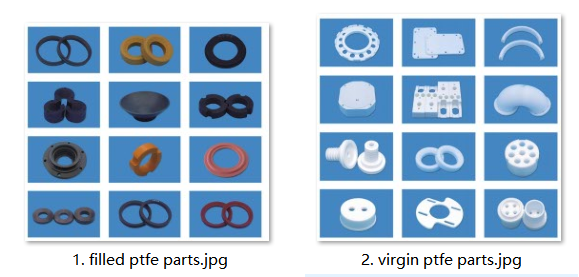

DISPLAY FOR MODIFIED AND VIRGIN PTFE PARTS

Modified ptfe parts could be piston teflon rings, carbon fiber filled ptfe support ring, bronze filled ptfe wear ring, Ptfe support ring etc

We are professional ptfe parts manufacturer who can make different shape of ptfe parts, and give you professional suggestion about the available material or design according to your working situation.

More info pls get in touch with us by email sales@topseals.com.cn

FAQs

We are making our greatest efforts to offer you the quality rubber seals and plastic parts products at good price. We’d like to cooperate with you to expand our business in your markets.If in doubt, please see the following FAQs

Q: Are you a trading company or manufacturer ?

Q: what do you need for a free quote ?

Q: what is your leadtime normally ?

Q: what is your MOQ ?

Q: How about your payment terms ? How do I pay you ?

Get a free quote

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message