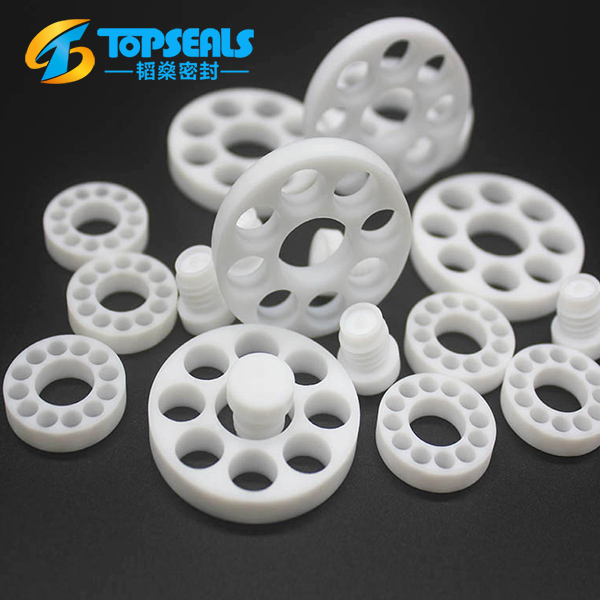

PTFE Back-up rings

PTFE gasket | PTFE washer | PTFE seals

PTFE gaskets | PTFE Back-up rings are used with a primary seal such as an o-ring in both dynamic and static applications to prevent extrusion of the oring when it is subject to high pressures.

Inquire Now

Descriptions

PTFE back up ring

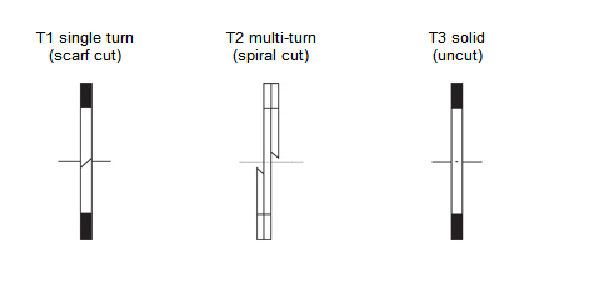

THE TYPE OF PTFE GASKETS OR BACK UP RINGS

There are three basic types on Teflon back-up rings for standard back up rings, solid backup rings, split backup rings and spiral backup rings and the drawing as below for your ref.

And customized gaskets also could be available for us if you have drawing or specification details.

What is PTFE ?

Polytetrafluoroethylene (Teflon or PTFE or F4) is one of the best corrosion resistant materials in the world, so it is known as the "King of Plastics". It can be used in any kind of chemical medium for a long time, and its production has solved many problems in chemical, petroleum, pharmaceutical and other fields in China.

The PTFE pad, PTFE gasket and PTFE sealing gasket are made of suspension polymerization PTFE resin molding. Compared with other plastics, polytetrafluoroethylene has excellent chemical corrosion resistance and temperature resistance. It has been widely used as sealing materials and filling materials.

It has high chemical stability and excellent chemical corrosion resistance, such as resistance to strong acid, strong alkali, strong oxidant, etc. It has outstanding heat resistance, cold resistance and friction resistance. The long-term use temperature range is - 190~260 ° C. It also has excellent electrical insulation and is not affected by temperature and frequency. In addition, it is non stick, non absorbent and non burning. Suspension resin is generally molded and processed by molding and sintering. The rods, plates or other profiles can be further machined by planing, drilling, milling and other machining methods. After turning and drafting, the bar can be made into oriented film.

Becasue of its Excellent Chemical stability, corrosion resistance, air tightness, high lubricity, non stick and conductivity. Good insulation and aging resistance. It can be used as engineering plastics Made of polytetrafluoroethylene pipe, ptfe rod, ptfe belt, ptfe plate, ptfe film, etc. It is generally used for corrosion-resistant pipes, containers, pumps, valves, radar and high-frequency communication Equipment, radio equipment, etc.

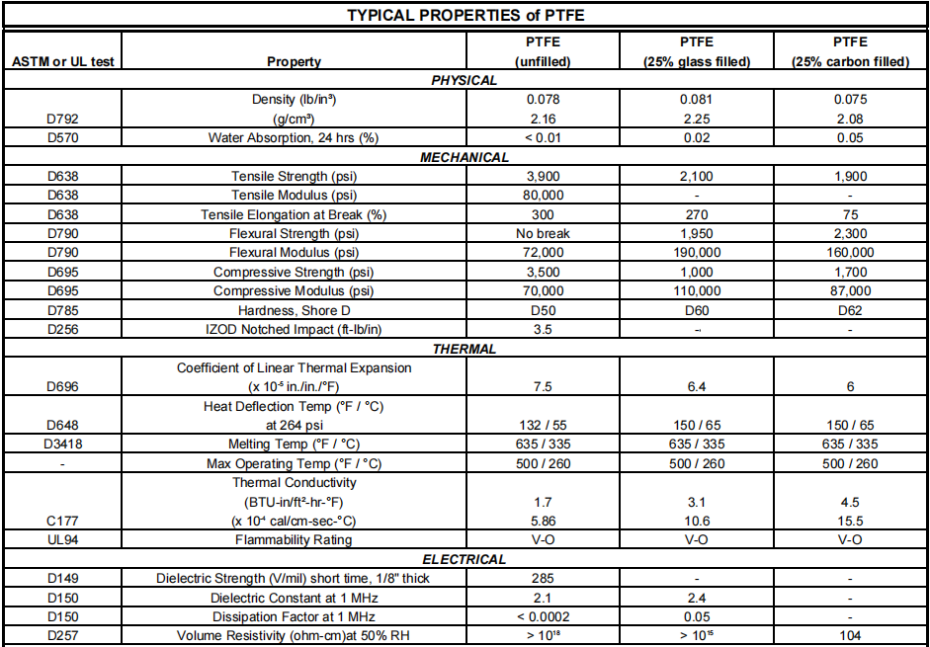

VIRGIN PTFE AND FILLED PTFE MATERIAL PROPERTY

ADVANTAGE OF PTFE MATERIAL

- Great Chemical compatibility corrosive reagents – this means that most chemicals don’t affect it & so it’s the go-to choice for most industries. It’s often used as a gasket where aggressive chemicals are used

- Low friction, this means that moving parts that are coated in PTFE will slide with ease, causing less heat, less wear & tear & reducing fire risk. PTFE’s coefficient of friction is the third-lowest of any known solid material

- Massive range of temperture resistance, its rangs will be be between -100°C to 280°C

- Non stick ability, so it could self-cleaning and not easy to stick to any dirt

- Great electrical properties, PTFE offers high electrical resistance and dielectric strength, so it could be widly used in electric components.

- Excellent moistrue resistant, making it a great barrier to water & resistant in all ranges of humidity

- Aging resistance, PTFE is an extremely durable material. For example, it is not affected by ultraviolet and is resistant to oxidation, discoloration, and embrittlement

- Non-flammability, PTFE offers extraordinary resistance to high temperature and flames because it has a very high melting point and auto-ignition temperature

- Low refractive index, means ptfe product’s visual appearance won’t change after light exposure

Application

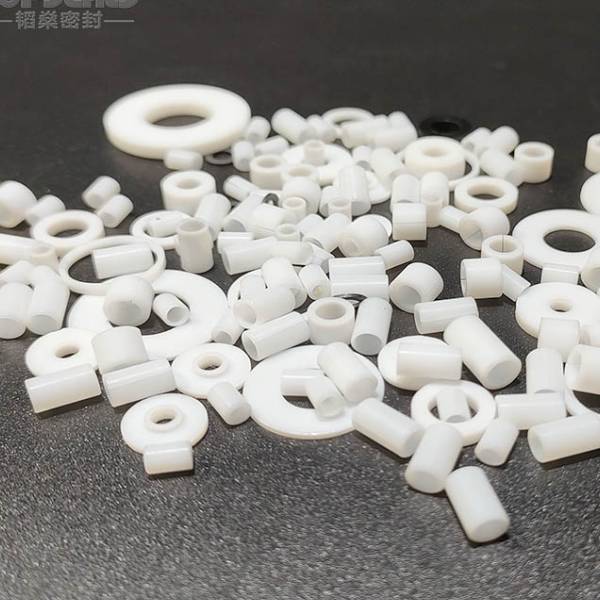

PTFE Could be made as PTFE Seals, PTFE bushings or sleeves , PTFE back-ups or gaskets, PTFE guides, PTFE pads, PTFE plugs, PTFE rollers, PTFE spacers, PTFE o-rings, PTFE wear rings, PTFE washers, PTFE adaptor etc.

PTFE's mechanical properties are low compared to other plastics, But its mechanical properies can be enhanced by adding fillers such as galss firbers, carbon, graphite, molybdenum disulphide and bronze etc.

PROCESS

CNC Turning , milling, cutting, molding etc

FAQs

We are making our greatest efforts to offer you the quality rubber seals and plastic parts products at good price. We’d like to cooperate with you to expand our business in your markets.If in doubt, please see the following FAQs

Q: Are you a trading company or manufacturer ?

Q: what do you need for a free quote ?

Q: what is your leadtime normally ?

Q: what is your MOQ ?

Q: How about your payment terms ? How do I pay you ?

Get a free quote

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message