Perfluoroelastomer (FFKM) O-Rings

FFKM O-Rings | FFKM Seals | FFKM Gaskets

FFKM o rings not only has excellent high temperature resistance and chemical resistance as PTFE, but also retains the relevant properties of rubber elastomer. It can be used continuously at 260 ° C to 300 ° C and at a high temperature of 325 ° C in a short time. Such excellent performance makes it widely used in military industry, aerospace, semiconductor, medicine, electronics, chemical industry and other fields.

Inquire Now

Descriptions

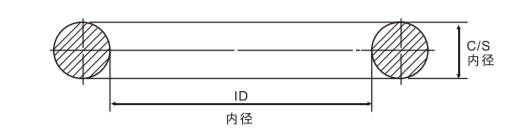

1. Construction of FFKM o rings:

Normally, rubber o rings sizes are specified by the inside diameter (ID) and the cross section diameter (CS), and AS568, ISO3601 and JIS standard size and customized size are available.

2. FFKM Material Property

Ffkm (kalrez) perfluoroether rubber material is the best rubber material with high temperature resistance, strong acid-base resistance and organic solvent resistance among all elastic sealing materials at present. Perfluoroether rubber can resist the corrosion of more than 1600 chemical solvents such as strong acids, strong alkalis, organic solvents, ultra-high temperature steam, ethers, ketones, esters, nitrogen-containing compounds, hydrogen carbide, alcohols, aldehydes, furans and amino compounds. The high temperature resistance can reach 320 ℃. Ffkm perfluoroether parts have more than 40 years of practical application experience in many industries.

3. FFKM Physical propertyies Table

Topseals use imported perfluoroether ffkm rubber raw materials to meet the special sealing needs of customers under harsh working conditions. Due to the complex manufacturing process of perfluoroether rubber, only a few manufacturers in the world can produce perfluoroether rubber raw materials: American DuPont kalrez perfluoroether rubber, American 3M perfluoroether rubber, Japan Daikin perfluoroether rubber, European Solvay perfluoroether rubber, etc.

According to different temperature resistance grades and raw material performance formulas, Topseals has the following different grades of perfluoroether ffkm materials for choosing.

| FFKM | Temperature | Tensile Strength |

Elongation at bread |

100% Modulus |

Hardness | Comprssion Set |

| Type No. | ℃ | Mpa | % | Mpa | Shore A | 70 hours |

| 9B23 | 230 | 21.2 | 91 | / | 90 | 26% @200℃ |

| 9625 | 250 | 11.6 | 260 | 4.3 | 75 | 20% @200℃ |

| 9650 | 290 | 16.7 | 193 | 13.5 | 80 | 18% @200℃ |

| 9630 | 300 | 15.2 | 186 | 12.4 | 75 | 19% @200℃ |

| 9655 | 320 | 20 | 175 | 10.5 | 70 | 19% @200℃ |

Remarks:

1)Perfluoroether ffkm has a type with high cleanliness and no metal ions to choose . And Normally, the hardness could be from 65 shore-A to 90 Shore-A. For specific consultation, please contact topseals' sales engineer.

2)The above testing results are provided by Topseals company based on testing testing slabs or buttons. and the results from the actual parts could be different. It is the users responsibility to ensure material is suitable for its intended application prior to purchase. for further information on this date sheet pls contact us freely.

4. Application Industry

FFKM perfluoroether rubber seals are mainly used in semiconductor industry, chemical industry, automobile industry, petroleum industry, pharmaceutical industry, battery industry, nuclear power industry and other harsh working conditions.

5. Application Conditions

Due to the high cost of perfluoroether ffkm rubber raw materials, the working conditions of perfluoroether ffkm sealing are usually very harsh, and other rubber raw materials can not meet the sealing requirements under these harsh working conditions. Under these harsh working conditions, other rubbers are prone to corrosion, swelling, dissolution, aging and hardening, resulting in seal failure. Due to its excellent corrosion resistance and high temperature resistance, perfluoroether ffkm rubber not only meets the sealing requirements under harsh working conditions, but also increases the service life of seals and reduces the maintenance cost of customers.

Typical application conditions of perfluoroether ffkm rubber seals include:

*Semiconductor industry (plasma corrosion, gas corrosion, acid-base corrosion, high temperature corrosion, high cleanliness requirements of rubber seal)

*Pharmaceutical industry (organic acid corrosion, organic alkali corrosion, organic solvent corrosion, high temperature corrosion)

*Chemical industry (strong acid corrosion, strong alkali corrosion, gas corrosion, organic solvent corrosion, high temperature corrosion)

*Petroleum industry (heavy oil corrosion, hydrogen sulfide corrosion, high sulfide corrosion, organic composition corrosion, high temperature corrosion)

*Automotive industry (high temperature oil corrosion, high temperature corrosion)

*Laser electroplating industry (high temperature corrosion, high cleanliness perfluoroether rubber can not precipitate metal ions)

*Battery industry (acid-base corrosion, strong active medium corrosion, strong oxidizing medium corrosion and high temperature corrosion)

*Special equipment manufacturing industry (strong acid-base corrosion, gas corrosion, high temperature corrosion, organic solvent corrosion, ion corrosion)

*Special chemical industry (strong oxidant corrosion, strong active agent corrosion, concentrated acid-base corrosion and organic solvent corrosion)

*Nuclear power and thermal power industry (high temperature steam corrosion, ultra-high temperature water corrosion, nuclear radiation corrosion)

6.Temperature: - 20℃ ~ 320℃

7.Hardness range: 65 shore-A to 90 Shore-A

8.Color: black , white, red etc, according to clients' needs

Topseals can make FFKM O-rings with internation standard, or to make non- standard size ffkm perfluoroether O-rings according to the size required by customers.

9.Related Material's Property

Topseals's fluorocarbon (FKM, FPM) O-rings are compatible with oils and gases, hydraulic oil and fuels.

Topseals's hydrogenated nitrile (HNBR, HSN) O-rings are very compatible with oils and gases.

Topseals's ethylene propylene rubber (EPM, EPR, EPDM) O-rings are compatible with solvents and other chemicals.

Topseals's silicone (VMQ) O-rings are very compatible with PFPE, cold water, and ozone.

Topseals's polychloroprene rubber (CR) O-rings are compatible with oils and gases.

Topseals's perfluoroelastomer ( FFKM) O-rings are very compatible with hydraulic oil and fuels.

Topseals's nitrile rubber (NBR) O-rings are very compatible with oils and gases.

Topseals's fluorosilicone (FVMQ) O-rings are very compatible with oils and gases.

FKM compounds are widely used in chemical, automotive, aerospace and industrial applications, Fluoroelastomer (Viton®, FKM) offers a wide range of resistance to chemicals, oil and heat, with situational service life above 200°C, with Excellent mechanical properties. Good extrusion resistance. Chemical and heat resistant.

NBR offers relative low cost, good mechanical properties, and resistance to many common oils, fuels and lubricants. NBR has poor resistance to weathering, sunlight and ozone so it is best used in enclosed environments where parts are not exposed to the elements.

HNBR Hydrogenated versions of NBR (HNBR) have enhanced mechanical properties as well as greater thermal and chemical stability. Specific physical properties and chemical resistances vary by compound formulation.

Silicone are excellent seal materials for extreme temperature in static applications. Outstanding flex and fatigue life, very good for ozone and UV radiation, insulating properties, and physiologically neutral. silicones can be synthesized with a wide variety of properties and compositions.

PTFE with Best chemical compatibility, low friction, meets FDA, USDA and 3-A dairy requirements, excellent moisture resistant and good cryogenic capabilities down to -350° F. Could be applied in Seals, bushings, back-ups, guides, pads, plugs, rollers, spacers, o-rings, wear rings, washers.

FAQs

We are making our greatest efforts to offer you the quality rubber seals and plastic parts products at good price. We’d like to cooperate with you to expand our business in your markets.If in doubt, please see the following FAQs

Q: Are you a trading company or manufacturer ?

Q: what do you need for a free quote ?

Q: what is your leadtime normally ?

Q: what is your MOQ ?

Q: How about your payment terms ? How do I pay you ?

Get a free quote

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message