Rubber stopper | silicone plugs supplier

2022-11-06 | Blog Message

SILICONE RUBBER PLUGS FOOD GRADE

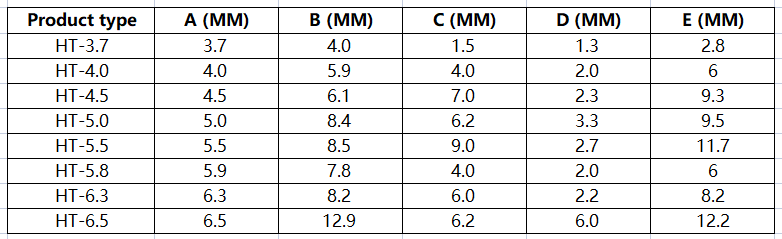

Rubber plugs could be different type, such as solid T shape plugs, blanking plug tube pipe end cap , rubber plugs with screw thread head etc.

Many size in stock for silicone rubber plugs, rubber hole plugs, rubber inserts, rubber end caps etc.

Custom type also can be available, material also could be NBR, FKM, EPDM, SR etc.

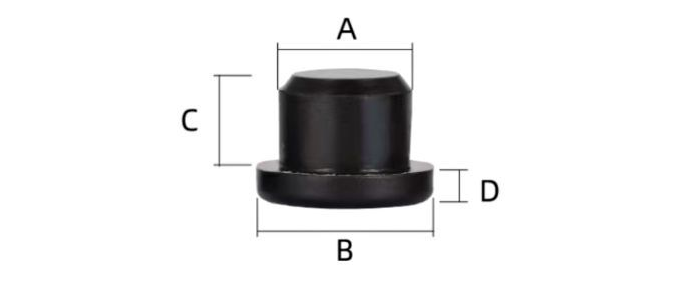

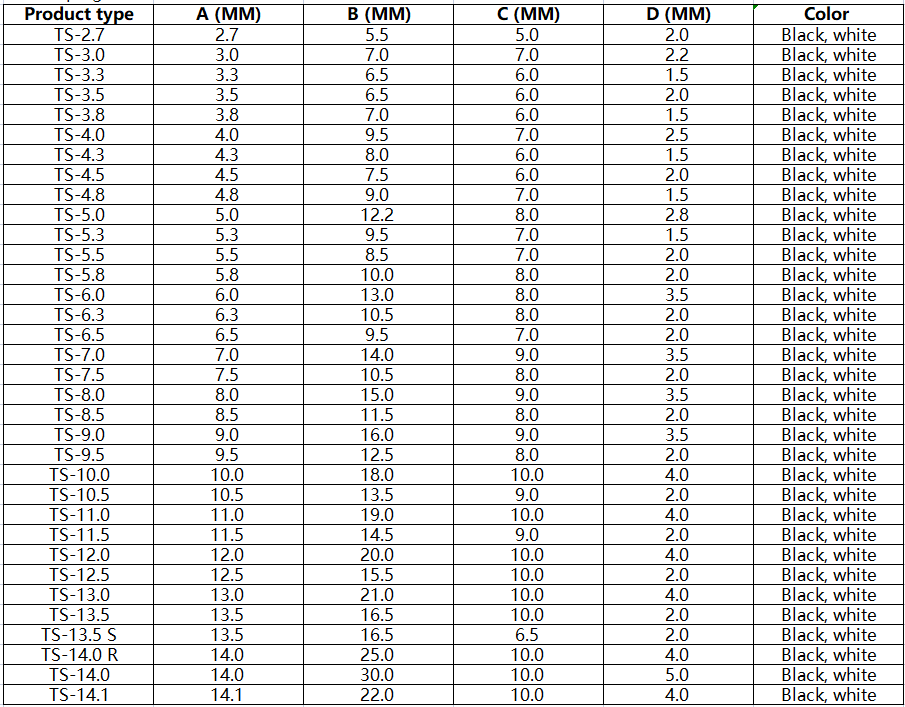

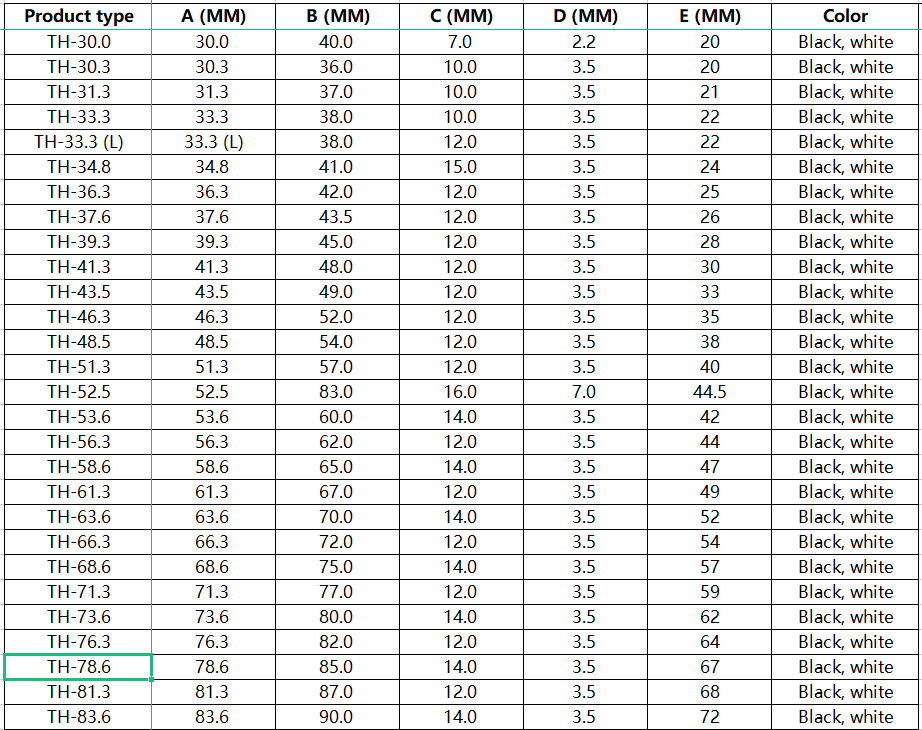

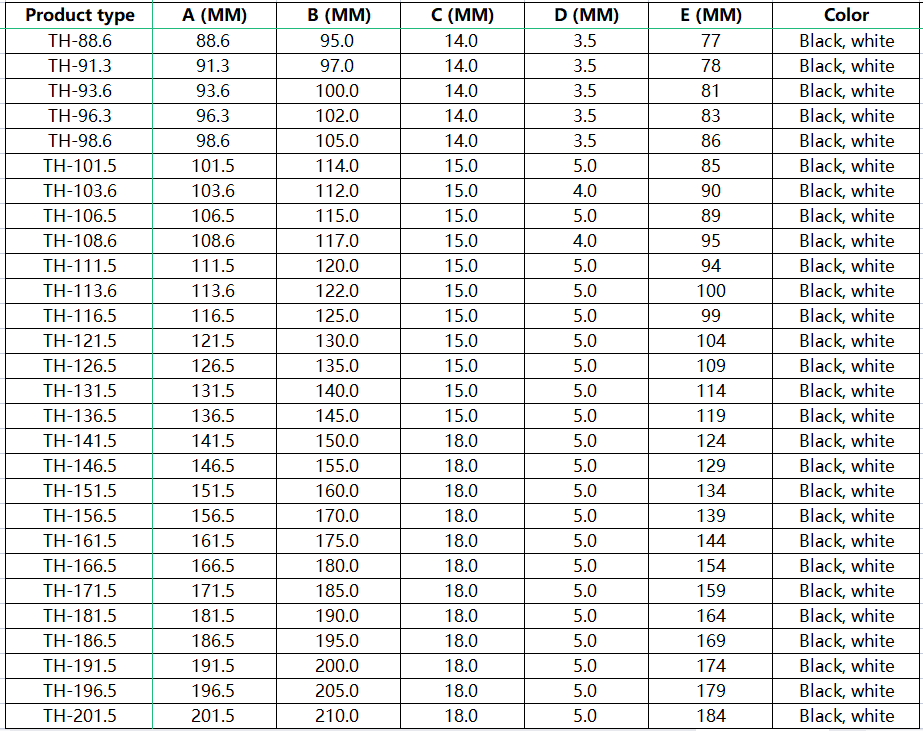

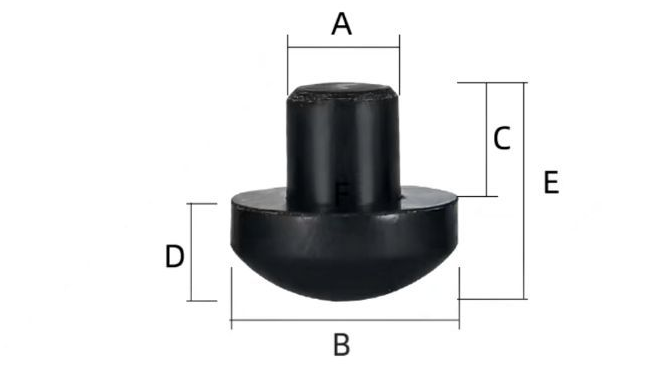

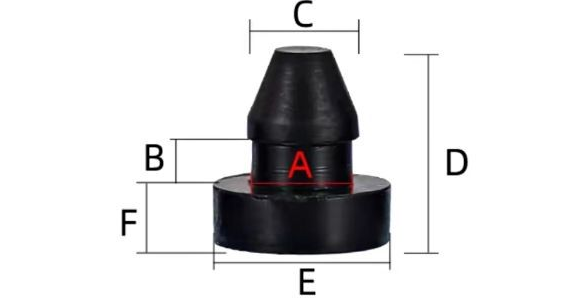

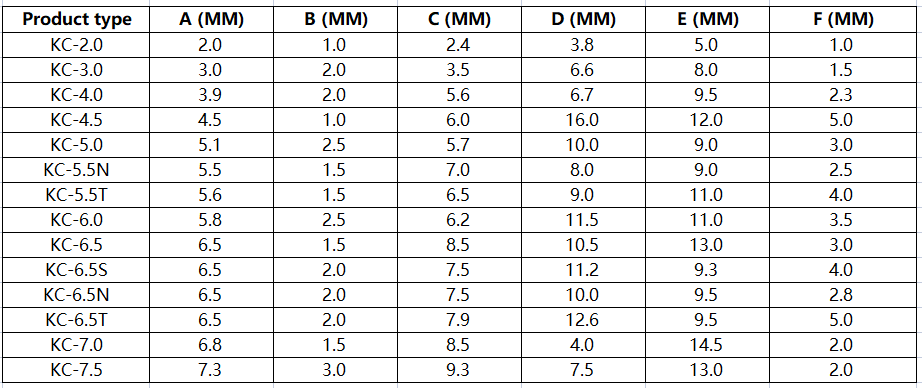

T shape solid Rubber Blanking End Cap Inserts Seal Plug Stopper

blanking plug tube pipe end cap stopper seals silicone rubber food grade

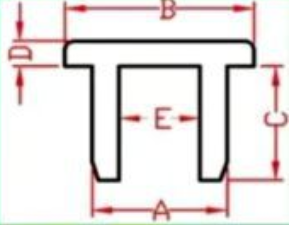

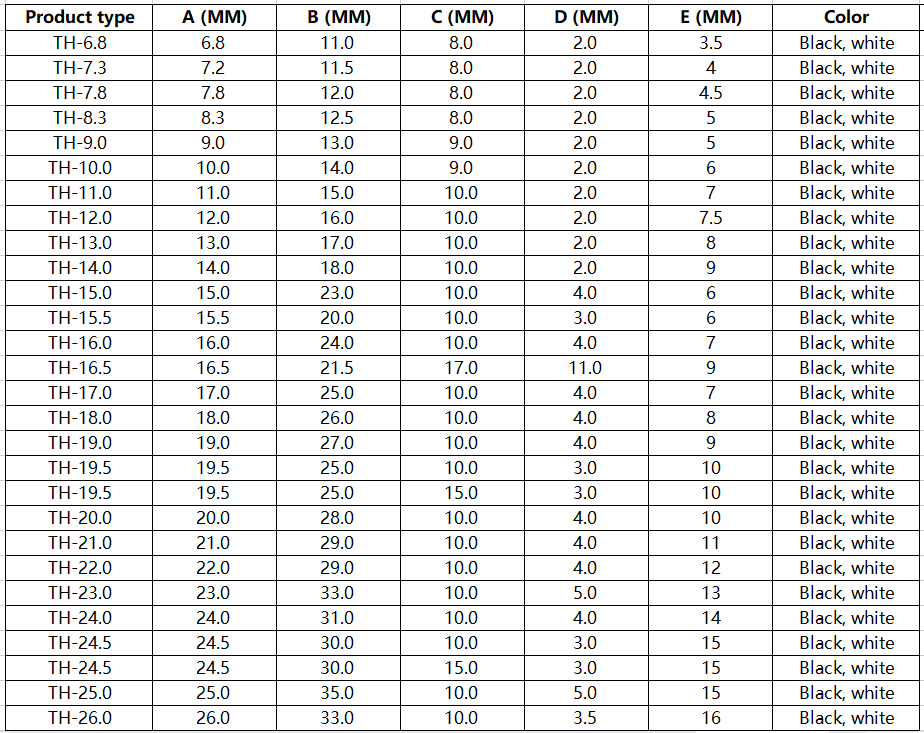

T-shaped rubber plugs with curved head

Rubber plugs with slot

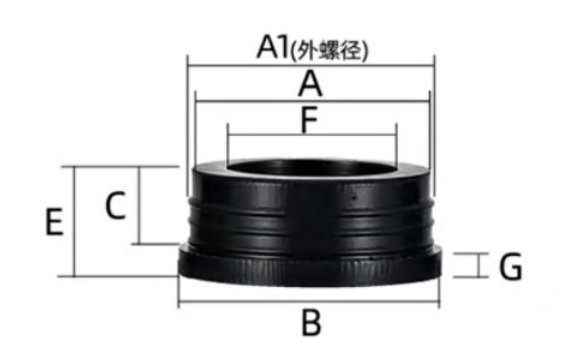

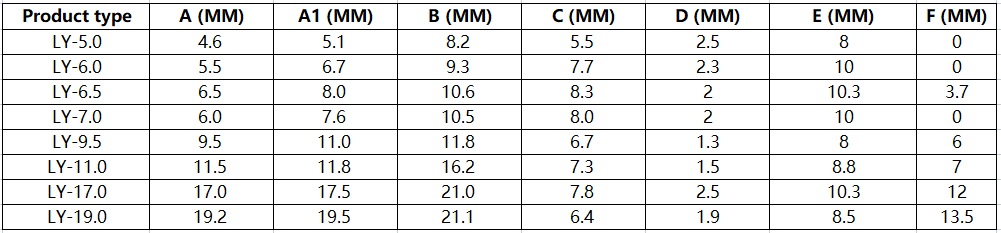

rubber plugs with Screw thread

Topseals is a rubber silicone plugs supplier & rubber stopper manufacturer, and we have many size of silicone plugs, silicone stoppers, hole rubber stopper,rubber inserts, rubber nut inserts, in stock, welcome to sent us a inquiry for any rubber parts whatever standand size or custom size & type.

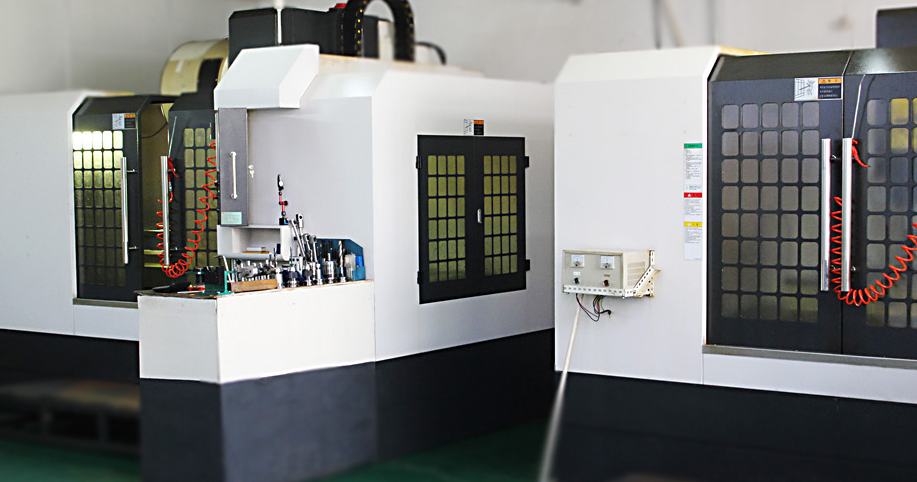

MOULD CENTER FOR RUBBER PARTS

Topseals have own mould center to make us have a fast leadtime for mould, normally 7 days or so, could be 2-3days.

TOPSEALS' MOULD WAREHOUSE

RAW MATERIAL PROPERTY

E - Excellent G - Good F - Fair P - Poor

| Property | NBR | EPDM | CR | Silicone | FKM | NR | SBR | PU | HNBR | FVMQ | IIR | Aflas |

| Abrasion Resistance | G | G | G | P | G | E | E | E | G | P | G | G |

| Acid Resistance | F | G | F | F | E | F | F | P | E | F | G | E |

| Chemical Resistance | F | E | F | G | E | F | F | F | G | E | E | E |

| Cold Resistance | G | G | F | E | P | G | G | G | G | G | G | P |

| Compression Set Resistance | G | G | F | G | E | G | G | F | G | G | F | G |

| Dynamic Properties | G | G | F | P | G | E | E | E | G | P | F | G |

| Electrical Properties | F | G | F | E | F | G | G | F | F | E | G | E |

| Elongation | G | G | G | F | F | F | F | F | G | F | G | F |

| Flame Resistance | P | P | G | F | E | P | P | P | P | G | P | E |

| Heat Resistance | G | G | G | E | E | F | F | F | E | E | G | E |

| Impermeability | G | G | G | P | G | F | F | G | G | P | E | G |

| Oil Resistance | E | P | F | F | E | P | P | G | E | G | P | E |

| Ozone Resistance | P | E | G | E | E | P | P | E | G | E | G | E |

| Tear Resistance | F | G | F | P | F | G | G | G | F | P | G | P |

| Tensile Strength | G | G | G | P | G | E | E | E | E | F | G | G |

| Water Resistance | G | E | F | G | F | G | G | P | E | F | G | G |

| Weather Resistance | F | E | E | E | E | F | F | E | G | E | G | E |

Topseals's fluorocarbon (FKM, FPM) O-rings are compatible with oils and gases, hydraulic oil and fuels.

Topseals's hydrogenated nitrile (HNBR, HSN) O-rings are very compatible with oils and gases.

Topseals's ethylene propylene rubber (EPM, EPR, EPDM) O-rings are compatible with solvents and other chemicals.

Topseals's silicone (VMQ) O-rings are very compatible with PFPE, cold water, and ozone.

Topseals's polychloroprene rubber (CR) O-rings are compatible with oils and gases.

Topseals's perfluoroelastomer ( FFKM) O-rings are very compatible with hydraulic oil and fuels.

Topseals's nitrile rubber (NBR) O-rings are very compatible with oils and gases.

Topseals's fluorosilicone (FVMQ) O-rings are very compatible with oils and gases.

MAIN RAW MATERIAL PROPERTY

FFKM perfluoroelastomer compounds are has excellent high temperature resistance and chemical resistance as PTFE, but also retains the relevant properties of rubber elastomer. It can be used continuously at 260 ° C to 300 ° C and at a high temperature of 325 ° C in a short time. Such excellent performance makes it widely used in military industry, aerospace, semiconductor, medicine, electronics, chemical industry and other fields.

FKM compounds are widely used in chemical, automotive, aerospace and industrial applications, Fluoroelastomer (Viton®, FKM) offers a wide range of resistance to chemicals, oil and heat, with situational service life above 200°C, with Excellent mechanical properties. Good extrusion resistance. Chemical and heat resistant.

NBR offers relative low cost, good mechanical properties, and resistance to many common oils, fuels and lubricants. NBR has poor resistance to weathering, sunlight and ozone so it is best used in enclosed environments where parts are not exposed to the elements.

HNBR Hydrogenated versions of NBR (HNBR) have enhanced mechanical properties as well as greater thermal and chemical stability. Specific physical properties and chemical resistances vary by compound formulation.

Silicone are excellent seal materials for extreme temperature in static applications. Outstanding flex and fatigue life, very good for ozone and UV radiation, insulating properties, and physiologically neutral. silicones can be synthesized with a wide variety of properties and compositions.

PTFE with Best chemical compatibility, low friction, meets FDA, USDA and 3-A dairy requirements, excellent moisture resistant and good cryogenic capabilities down to -350° F. Could be applied in Seals, bushings, back-ups, guides, pads, plugs, rollers, spacers, o-rings, wear rings, washers.