ptfe o ring

2023-04-04 | Blog Message

The introduction of Material PTFE

Polytetrafluoroethylene PTFE F4 is one of the best corrosion resistant materials in the world today, so it is called "the king of plastics".

It can be used in any kind of chemical medium for a long time, and its emergence has solved many problems in China's chemical, petroleum, pharmaceutical and other fields.

Coils, gaskets, PTFE seals, gaskets and sealing washers are made of suspension polymerized PTFE resin molding.

Compared with other plastics, tetrafluoroethylene has excellent chemical corrosion resistance and temperature resistance. It has been widely used as a sealing material and filling material.

It has high chemical stability and excellent resistance to chemical corrosion, such as strong acid, strong alkali, strong oxidant, etc

Heat resistance, cold resistance and friction resistance. The temperature range for long-term use is - 190~260 ° C. It also has excellent electrical insulation and is not affected by temperature

And frequency. In addition, it has the characteristics of non-stick, non-absorbent and non-burning. Suspension resin is generally molded and sintered.

The bar, plate or other profiles can be further processed by planer, drilling, milling and other machining methods. The bar can be made into directional film by turning and drawing.

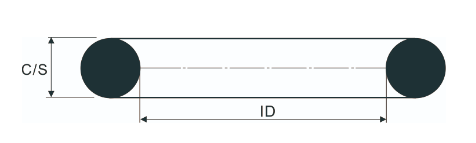

The drawing of PTFE o rings

Size could be standard or customized, pls leave your request ID and C/S for offer pls.

Related production

PTFE sealing ring, PTFE seals, bronze filled ptfe wear ring,ptfe wear ring,ptfe back up ring,ptfe encapsulated viton o ring,